-

Are you dealing with the presence of asbestos in your facility? Here’s our answers to some frequently asked questions.

What is asbestos?

Asbestos is a naturally occurring mineral made up of long, thin, easily separated fibrous bundles. Asbestos was added to building materials to make them stronger and more temperature resistant. Buildings constructed as late as the 1990s may contain asbestos-containing materials (ACM) or presumed ACM (PACM) in materials such as insulation, floor and ceiling tile, roofing materials, or cementitious panels. Asbestos-containing materials that aren’t damaged or disturbed are not likely to pose a health risk; however, these materials may release fibers when they are damaged, removed improperly, cut, torn, sanded, sawed, or otherwise disturbed. Inhaling the airborne, microscopic fibers can result in lung diseases such as asbestosis, lung cancer, or mesothelioma.

There are many challenging factors to consider when dealing with the presence of ACM in a facility. The well-being and health of building occupants, including the health and safety of the general public and contractors that may be present at your facility, and regulatory compliance are all challenges that must be met head-on.

What’s the first step if ACM is suspected?

The first step for any building owner is to determine whether ACM or PACM (presumed asbestos-containing material) is present within the facility through an asbestos survey conducted by a United States Environmental Protection Agency-accredited asbestos building inspector. A trained and accredited asbestos professional building inspector knows what to look for and how to safely collect samples of suspect ACM. Depending on the size of a facility, and how many suspect materials are present, an asbestos survey can take several hours, days, or longer.

What happens if ACM is present?

If it is determined through an asbestos survey that ACM is present in a facility, the next step is to implement an Operations and Maintenance Program to manage the ACM and protect occupants and employees from potential exposure.

What’s in an Operations and Maintenance Program?

The purpose of an Operations and Maintenance (O&M) Program is to document the presence of ACM in a facility, describe and document response actions, and verify required employee training records. The O&M Program must remain in effect until all asbestos is removed from a facility. The Occupational Safety and Health Administration (OSHA) regulations that cover ACM are:

- Title 29 CFR 1910.1001 — General Industry

- Title 29 CFR 1926.1101 — Construction Industry

The general industry regulations apply when site personnel or contractors undertake activities that may put them in contact with ACM and could expose them and other employees to airborne asbestos if the materials are or have been disturbed. The construction industry regulations apply when site personnel or contractors remove or intentionally disturb ACM.

Are you required to have all ACM abated?

The short answer: Not necessarily. Of course, having it all properly removed, or abated, is certainly an option. However, depending on the amount of ACM in a facility, its location, and its condition, it may be a very costly endeavor for a business on a budget. Not to mention, once the ACM is removed, new materials will likely need to be installed to replace the abated ACM, adding more costs to the project.

What other options are there besides complete abatement?

Fortunately, there are other options, such as managing the ACM in place through enclosure or encapsulation. Enclosure is just what the name suggests; covering or placing an enclosure over an ACM material to prevent fiber release. Encapsulation is the treatment of ACM with a sealant material that surrounds or embeds asbestos fibers in an adhesive matrix to prevent the release of fibers. Again, depending on the type, condition, and location of ACM in a facility, some options may be better than others.

What’s an example of enclosure?

A facility has confirmed through an asbestos building inspection that the floor tile in the reception and lobby areas is ACM. Due to budget constraints, the owner has decided to install new, non-ACM floor tile over the existing tile. This is an example of enclosure of existing ACM.

What’s an example of encapsulation?

A facility has confirmed through an asbestos building inspection that the pipe insulation in the mechanical room is asbestos containing. The inspection report has indicated that the pipe insulation is in damaged condition. A professional asbestos contractor is hired to treat the material with a sealant that binds the asbestos fibers together and coats the material in a way that fibers are not released. This is an example of encapsulation of existing ACM.

Does enclosure or encapsulation mean the hazard is completely gone?

Although the risk of disturbance is reduced in these scenarios, the hazards still exist. For example, if a maintenance worker drills into or uses a rotary tool to cut the layers of floor tile, that worker and other employees in the area could be exposed to airborne asbestos fibers. For this reason, OSHA regulations require labeling of ACM or PACM where feasible.

What does OSHA require when ACM or PACM is present?

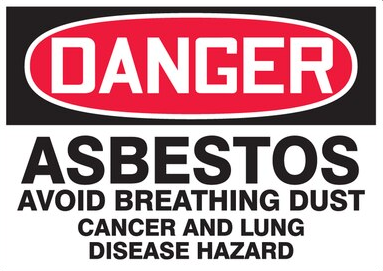

Signage: Warning labels should be attached or adjacent to areas where ACM or PACM is present (e.g., boiler rooms). Warning signs should be clearly visible and contain language that is neither too vague nor alarming. OSHA does allow the use of general area signs and other alternative methods in lieu of extensive labeling in some

cases.

cases.Training: In addition to labelling ACM in a facility, employers, building owners, and managers must institute a training program for all employees whose jobs require them to work in areas where known, suspect, or PACM is present. Training of employees to establish awareness and comprehension of proper asbestos-related work practice is one of the most important aspects of an effective O&M program.

Communication to building occupants and training play a huge role in mitigating potential asbestos hazards within a facility. Building occupants, employees, and others who are aware of the presence of ACM are less likely to disturb these materials and cause unintentional fiber release.

Need assistance with managing asbestos hazards in your facility? EnSafe is here to assist! Please contact us to discuss custom solutions for your specific needs.