As we learned in Part 1, vapor intrusion (VI) is the migration of chemical vapors into a building from its subsurface (beneath its foundation). The vapors may originate from contamination within soil, groundwater, or other sources (for example, petroleum free product around a nearby underground storage tank). Part 2 addressed the identification of potential risks early in a project’s development to allow the appropriate level of VI investigation/mitigation to be integrated into the process.

How do we mitigate vapor intrusion threats?

Once investigations have determined that (a) indoor air has been impacted by vapor intrusion, or (b) soil gas poses a significant threat for VI (either now or in the future), mitigation may be required.

What is mitigation?

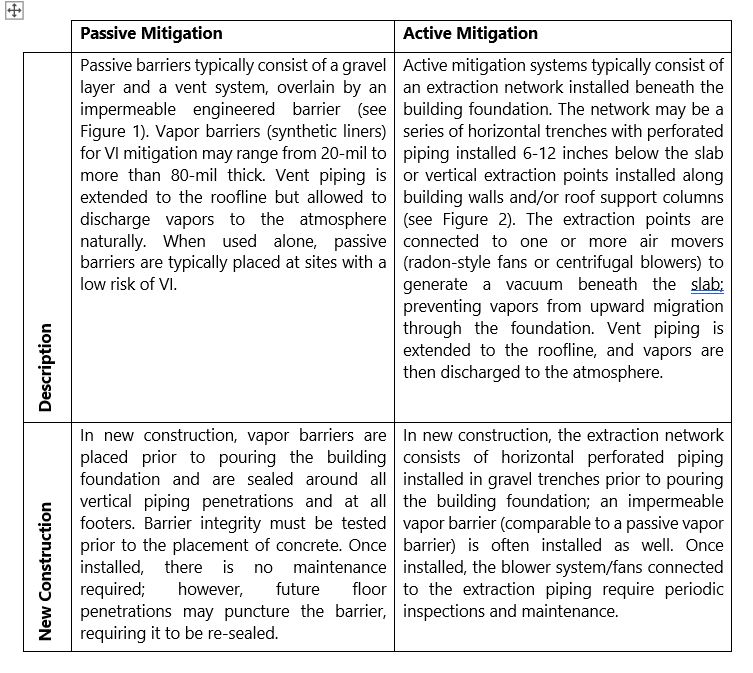

VI mitigation is an engineered intervention at a site that interrupts the vapor migration pathway and therefore prevents VI from occurring. Mitigation may be active or passive (see Table 1). VI mitigation is not the same thing as soil or groundwater remediation; it does not treat or eliminate the source. Mitigation will be required for as long as the source of vapors is present.

Active Mitigation Fan on Facility Roof

If mitigation is required, what are the next steps?

Since VI mitigation is most commonly required at existing industrial (manufacturing facilities) and commercial (gas stations and drycleaners) properties with slab-on-grade construction, mitigation is often accomplished by depressurizing (venting) the gravel/soil layer immediately beneath the floor slab. Other building designs (e.g., crawlspace, basement) may have different design approaches. To design a mitigation system beneath an existing slab-on-grade foundation, basic engineering tests (e.g., communications tests, or pressure field extension tests) are required to gauge the airflow potential beneath the slab. Tests at multiple points are typically performed in each structure, particularly if footers or other sub-slab structures (e.g., sumps) disrupt sub-slab continuity. Depending on the size of the area to be mitigated, these tests can take several hours to several days to complete. The data are then evaluated to determine the location and spacing of extraction points, vacuum requirements, and soil gas flow rates required to mitigate the targeted area. Once these design parameters are determined, the proper blower type, size, and capacity can be specified. For new construction, sub-slab vapor barriers (impermeable synthetic liner across the building footprint) are typically required and may be coupled with passive or active sub-slab depressurization.

Once the need for a mitigation system is identified, regulators will typically require a mitigation work plan with basic design elements. The results of communications tests and design evaluations are typically documented and submitted for regulatory approval. Installing a system typically requires the coordination of specialty subcontractors, including mechanical, electrical, and other sub-specialties.

What happens after the mitigation system is installed?

After installation, an active mitigation system may undergo a few weeks of fine tuning to make sure equipment is operating at maximum efficiency and the required sub-slab pressure field is being generated. The vacuum beneath the slab and in the various components of the system is one of the key optimization tools. Once optimized, the system should run efficiently with only periodic inspections and routine maintenance.

The regulatory agency will often require periodic indoor air sampling to gauge the effectiveness of the mitigation system. The frequency of sampling varies by agency but will often decrease over time as the system’s reliability is demonstrated.

This is the third of a three part series on VI. Part 1 was an overview of VI and when a property should be assessed for it. Part 2 discussed VI sampling and both qualitative and quantitative data evaluation. To learn more about EnSafe's VI capabilities, follow the link here. Part 1 and Part 2 are located here: Part 1 & Part 2.

Do you have questions related to vapor intrusion (VI)? Contact our experts today!